If you’re looking for the best resin 3D printers for miniatures in 2025, I’ve found that high-resolution options like the ELEGOO 8K and Saturn 3 MSLA 12K deliver incredible detail and smooth surface finishes. Resins like Siraya Tech Fast and TGM-7 offer strength and impact resistance, perfect for durable, finely detailed models. Choosing the right combination of printer and resin can dramatically improve your results—stay tuned to discover the top picks and expert tips.

Key Takeaways

- High-resolution LCD and MSLA printers (8K, 12K, 14K) enable ultra-fine detail for miniature modeling in 2025.

- Advanced resins with minimal shrinkage and high impact resistance improve surface finish and durability.

- Automated features like auto-leveling and resin detection streamline workflow and reduce errors.

- Large build volumes and fast curing times optimize efficiency for batch miniature production.

- Compatibility with software and cloud control enhances user experience and precision in detailed miniature creation.

ELEGOO 8K Photopolymer 3D Printer Resin (1000G)

Are you looking for a resin that delivers ultra-high detail and crisp finishes for your miniature projects? I recommend the ELEGOO 8K Photopolymer Resin (1000G). It’s specially formulated for 8K, 12K, and 14K LCD printers, ensuring stunningly sharp and smooth models. The resin’s low shrinkage results in precise features, reducing post-processing. It cures quickly, maintains stability, and provides vibrant colors like grey, white, black, and red. Plus, it’s easy to handle, with strong bed adhesion and minimal failures. Ideal for miniatures, scale models, and detailed accessories, it offers high-quality results with less effort, making it a top choice for detailed printing.

Best For: hobbyists and professionals seeking ultra-high detail, crisp finishes, and reliable performance for miniature, scale, and intricate models using 8K/12K/14K LCD 3D printers.

Pros:

- Produces highly detailed, sharp, and smooth models with minimal post-processing needed

- Fast curing times and excellent fluidity for efficient printing cycles

- Strong bed adhesion reduces failures and supports large, complex projects

Cons:

- Slight odor and potential for brittle thin parts in some prints

- Recent formulation updates may lead to inconsistent curing and performance issues

- Requires proper exposure settings and UV curing for full hardening, which may need calibration

TGM-7 3D Wargaming Resin for Miniatures

If you’re seeking a resin that combines high resolution with exceptional durability for miniature wargaming, TGM-7 3D Wargaming Resin is an excellent choice. It supports 4K/8K/12K LCD, DLP, and SLA printers, producing miniatures with sharp detail, a satin finish, and a neutral grey color. Known for toughness and resilience, it resists drops, impacts, chipping, and discoloration, making it ideal for handling and gameplay. While it requires careful handling due to its viscosity and longer curing times, the results are professional-grade, durable miniatures that require little touch-up. Despite its higher price, it’s worth it for gamers demanding quality and longevity.

Best For: serious miniature hobbyists and wargamers seeking highly detailed, durable, and professional-quality resin miniatures for tabletop gaming.

Pros:

- Produces high-resolution, sharp detail with a satin finish that mimics real plastic

- Exceptional toughness and impact resistance, reducing breakage during handling and gameplay

- Supports multiple high-end printers (4K/8K/12K LCD, DLP, SLA), ensuring versatility and consistent results

Cons:

- Higher cost compared to standard resins, which may be a barrier for some users

- Requires careful handling due to its viscosity and longer curing times, demanding more precise setup

- Slower printing and curing speeds compared to faster resins like ABS-like types

Chitu Systems Conjure Sculpt Resin 3D Printer

The Chitu Systems Conjure Sculpt Resin is an excellent choice for hobbyists and professionals seeking high-detail miniatures and display models. Its high-precision printing produces ultra-smooth surfaces with fine details, making it perfect for intricate miniature work. The resin’s durability surpasses standard options, nearly unbreakable when dropped from desk height, which adds to its appeal. While its higher viscosity improves surface quality, it can be a bit more challenging to print. Compatible with most LCD and DLP printers, it’s best used at 25-30°C for ideal results. Overall, Conjure Sculpt combines durability, precision, and surface quality for top-tier miniature creation.

Best For: hobbyists and professionals seeking high-detail, durable miniatures and display models with excellent surface finish.

Pros:

- Exceptional surface smoothness and fine detail for miniature work

- Highly durable, virtually unbreakable when dropped from desk height

- Compatible with most LCD and DLP 3D printers, offering versatility

Cons:

- Higher viscosity may make printing more challenging and require careful handling

- Slightly harder to print compared to standard resins

- Optimal printing temperature range (25-30°C) may require temperature control in cooler environments

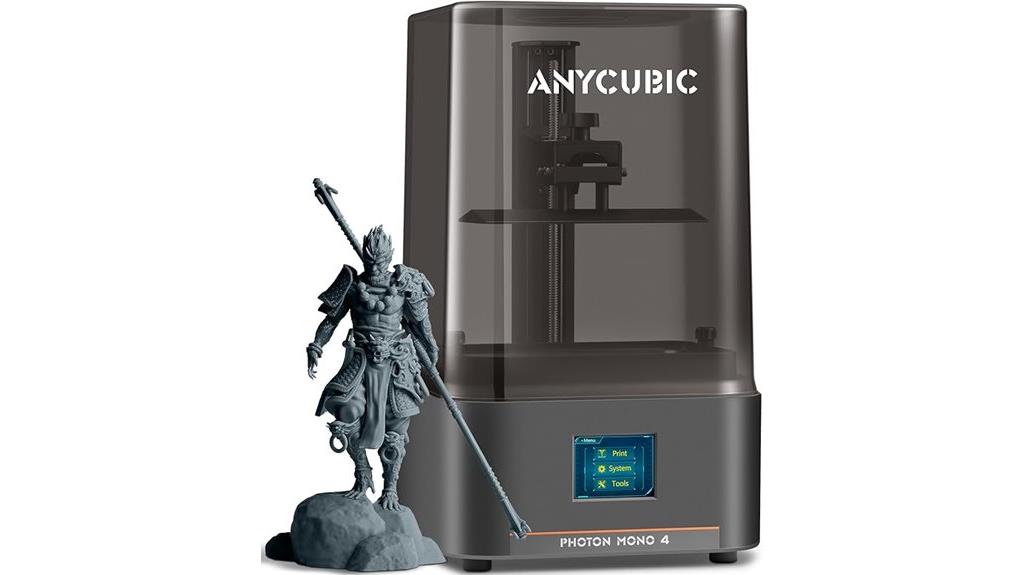

ANYCUBIC Photon Mono 4 Resin 3D Printer

For enthusiasts seeking highly detailed miniatures, the ANYCUBIC Photon Mono 4 delivers exceptional precision thanks to its 7.10K Mono LCD screen with a resolution of 9024×5120, making it ideal for capturing intricate features. The pixel size of just 17×17μm guarantees smooth surfaces and sharp details. Its advanced LightTurbo matrix light source provides stable, uniform illumination, reducing layer lines and rasterization. The generous build volume (6.04 x 3.42 x 6.49 inches) allows for larger models, while features like a 4-point leveling system and power-loss resume make operation straightforward. Overall, it’s a high-resolution powerhouse for miniature creators.

Best For: enthusiasts and professional miniatures makers seeking ultra-high-resolution resin prints with detailed features and smooth surfaces.

Pros:

- High-resolution 7.10K Mono LCD with 9024×5120 pixels for exceptional detail

- Stable, uniform illumination from Advanced LightTurbo matrix light source reduces layer lines

- Large build volume (6.04 x 3.42 x 6.49 inches) accommodates bigger models and complex designs

Cons:

- Maximum printing speed is limited to 70mm/h, which can be slow for large batches

- Does not support the Anycubic APP service, potentially limiting remote operation options

- Slightly complex initial setup with a 4-point leveling system may require careful calibration

ELEGOO Mars 5 Resin 3D Printer

The ELEGOO Mars 5 Resin 3D Printer stands out with its high-resolution 4K mono LCD and advanced COB light source, making it ideal for hobbyists and professionals who demand fine detail and intricate textures in miniature printing. Its automatic leveling and self-check features simplify setup and help prevent errors, saving time. The smart mechanical sensor detects resin residue to protect the LCD, while alarms notify you of resin shortages or leveling issues. With a compact design and a 5.65 x 3.53 x 5.91-inch build volume, it delivers precise, high-quality prints efficiently and reliably, perfect for detailed miniature projects.

Best For: hobbyists and professionals seeking high-resolution, detailed miniature prints with easy setup and reliable performance.

Pros:

- High-resolution 4K mono LCD with COB light source for detailed and textured prints

- Automatic leveling and self-check features simplify setup and reduce errors

- Intelligent monitoring systems protect the LCD and notify users of issues, ensuring continuous operation

Cons:

- Limited build volume size may restrict larger project printing

- Advanced features may require a learning curve for beginners

- Resin printing can be messy and requires proper handling and ventilation

ELEGOO ABS-Like 3D Printer Resin 3.0, 405nm UV-Curing Photopolymer Resin

If you need high-precision, durable models with smooth surface finishes, ELEGOO ABS-Like 3D Printer Resin 3.0 is an excellent choice, especially for functional prototypes and miniatures. Designed for 405nm UV curing, it’s compatible with a wide range of LCD, DLP, and MSLA printers, and optimized for ELEGOO devices. This resin offers high strength, impact resistance, and minimal shrinkage, ensuring detailed, accurate models that withstand mechanical stress. Its low viscosity allows for rapid curing and smoother printing, reducing print times and improving reliability. Overall, it’s perfect for creating intricate, robust miniatures with professional-quality surface finishes.

Best For: hobbyists, professionals, and manufacturers seeking high-precision, durable, and smooth-surfaced models for functional prototypes, miniatures, and industrial parts.

Pros:

- High strength, impact resistance, and toughness for durable models

- Minimal shrinkage ensures accurate, detailed surface finishes

- Low viscosity allows for rapid curing and smoother printing

Cons:

- Requires proper handling and ventilation due to chemical composition

- May need specific light exposure settings for optimal curing

- Cost could be higher compared to standard resins for casual users

Siraya Tech Fast 3D Printer Resin 2kg (Grey)

When precision and durability matter most in miniature printing, Siraya Tech Fast ABS-Like resin stands out as an excellent choice. This grey resin offers high mechanical strength, combining stiffness, toughness, and durability, making models resistant to falls and loads. It produces detailed, smooth surfaces with low shrinkage and high resolution, ideal for intricate miniatures and complex parts. Its fast curing time—around 0.5 seconds per layer—dramatically reduces print times, while delivering crisp details and excellent surface finish. Compatible with most LCD, DLP, and 8K printers, it’s reliable, cost-effective, and perfect for hobbyists and professionals seeking tough, high-quality miniatures.

Best For: hobbyists and professionals seeking high-precision, durable miniatures, intricate models, and small industrial parts with fast curing times and excellent surface finish.

Pros:

- Outstanding mechanical strength, toughness, and durability suitable for load-bearing and wear-resistant parts

- Fast curing time of around 0.5 seconds per layer drastically reduces print durations

- High resolution with smooth surfaces and minimal shrinkage, producing detailed and aesthetically pleasing models

Cons:

- Resin can separate into layers within two days if left unused, complicating storage and cleaning

- Handling uncured resin requires protective measures like gloves and good ventilation due to fumes and skin contact risk

- Disposal needs careful environmental consideration, avoiding drain disposal and requiring proper waste management

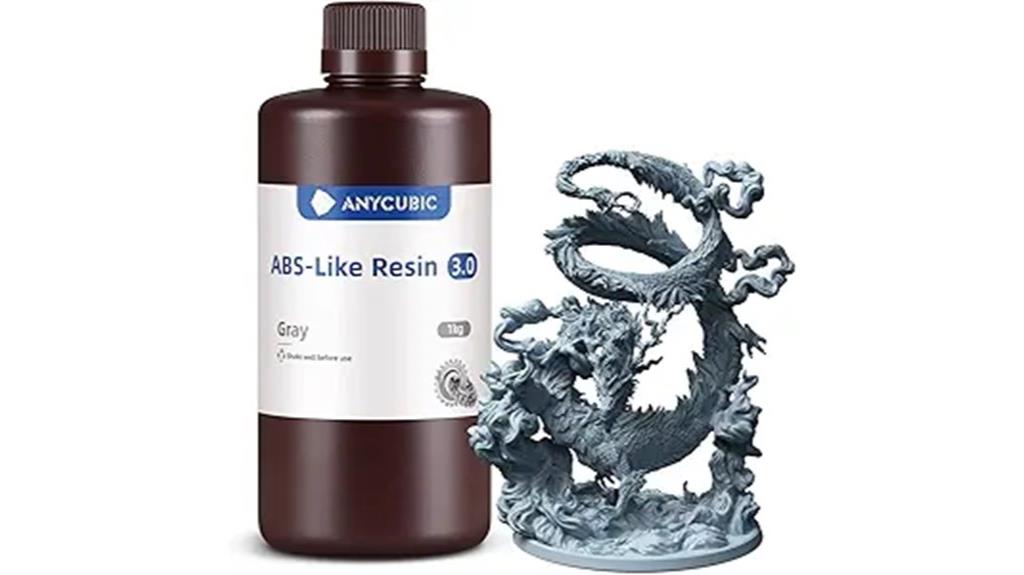

ANYCUBIC ABS-Like Resin 3.0 1kg

Anyone seeking durable, high-detail miniatures will find the ANYCUBIC ABS-Like Resin 3.0 1kg an excellent choice, thanks to its high strength and crack resistance. With a Shore Hardness of 86D, it resists cracking during drilling and handling, while its 30% elongation at break offers impressive resilience. This resin captures intricate details with low shrinkage and produces smooth, realistic textures. Its low viscosity speeds up printing and reduces overall time. Plus, it has minimal odor, making the process more comfortable. Compatible with all LCD and DLP printers within 365-405nm, it’s versatile and reliable for creating precise, impact-resistant miniatures.

Best For: hobbyists and professionals seeking durable, high-detail miniatures with excellent resilience and surface quality for various 3D printing applications.

Pros:

- High strength with a Shore Hardness of 86D, resisting cracks and deformation during handling and drilling

- Excellent detail capture with low shrinkage and smooth, realistic textures

- Fast curing and low viscosity reduce printing time and improve efficiency

Cons:

- May require proper ventilation despite minimal odor for safety during printing

- Compatibility limited to LCD and DLP printers within 365-405nm wavelength range

- Slightly higher cost compared to standard resins for some users

ANYCUBIC 3D Printer Resin, ABS-Like Resin Pro 2

The ANYCUBIC ABS-Like Resin Pro 2 stands out for its exceptional strength and durability, making it an ideal choice for those creating high-precision miniatures that need to withstand handling and wear. It offers over 100% increased elongation at break, reaching 35-40%, which means stronger, more resilient models. Its low shrinkage and high flowability guarantee sharp, detailed prints with minimal distortion. Compatible with all resin printers, it’s versatile and reliable for various projects. Plus, its low odor formulation provides a more comfortable printing environment. Overall, this resin combines toughness, precision, and ease of use, making it perfect for durable miniature creation.

Best For: hobbyists and professionals seeking high-strength, detailed, and durable miniatures and prototypes with minimal distortion.

Pros:

- Significantly increases model toughness and durability with over 100% elongation at break

- Ensures sharp, detailed prints with low shrinkage and high flowability for precision results

- Compatible with all resin 3D printers and formulated with low odor for a comfortable printing environment

Cons:

- May require adjustments in curing time due to its high flowability

- Slightly higher cost compared to standard resins with less durability

- Requires proper ventilation despite low odor formulation for extended use

Table Top RPG 3D Printing Resin by 3DRS (1kg)

If you’re looking for a resin that delivers exceptional detail and durability for your tabletop RPG miniatures, the 3DRS Table Top RPG 3D Printing Resin (1kg) is an excellent choice. It’s compatible with LCD, DLP, and SLA printers, curing quickly in about 2–2.5 seconds per layer. The resin produces sharp, detailed models with a smooth medium-grey finish perfect for painting. Its low shrinkage and high impact resistance guarantee your miniatures withstand handling and gameplay. Plus, it’s user-friendly, with minimal odor and easy cleanup, making it ideal for hobbyists and professionals seeking reliable, high-quality results in tabletop gaming and modeling.

Best For: hobbyists, professional model makers, and tabletop RPG players seeking detailed, durable miniatures and models with high precision and ease of use.

Pros:

- Produces high-resolution, sharp, and highly detailed miniatures and models

- Rapid curing time of approximately 2–2.5 seconds per layer enhances efficiency

- Low odor and easy cleanup improve the user experience and comfort during printing

Cons:

- Requires compatibility with LCD, DLP, or SLA printers, limiting use to certain equipment

- Slightly higher cost compared to standard resins may impact budget-conscious users

- Handling small, intricate parts may still require careful support removal and post-processing

ELEGOO Saturn 3 MSLA 12K 3D Printer

For enthusiasts seeking highly detailed miniatures, the ELEGOO Saturn 3 MSLA 12K stands out with its stunning 12K resolution and large build volume. Its 10-inch monochrome LCD offers a resolution of 11520×5120 pixels, providing incredibly fine detail with an XY resolution of 19×24μm. The printer can produce models up to 218.88×122.88×250 mm, perfect for larger projects. Its uniform 405nm light source and optical system guarantee consistent, high-quality prints. Protected by tempered glass and compatible with popular slicing software, the Saturn 3 combines speed, precision, and durability, making it an excellent choice for miniatures and intricate models.

Best For: enthusiasts and professionals seeking highly detailed miniatures and large-scale projects with exceptional accuracy and durability.

Pros:

- Ultra-high 12K resolution with fine XY resolution of 19×24μm for intricate detail

- Large build volume of 218.88×122.88×250 mm suitable for bigger models

- Uniform 405nm light source and high optical efficiency ensure consistent, high-quality prints

Cons:

- Higher price point compared to entry-level resin printers

- Slightly larger footprint requiring more space setup

- Requires careful handling of resin and post-processing for best results

ANYCUBIC 14K 3D Printer Resin (Grey, 1kg)

Anyone seeking ultra-fine detail and a matte finish in their miniature models should consider the ANYCUBIC 14K 3D Printer Resin. This grey resin offers 14K HD resolution with 0.15mm accuracy and ultra-fine tips at 0.02mm, capturing intricate details effortlessly. Its nano-ceramic powder creates a refined matte surface with minimized light interference, enhancing realism. The resin is also highly durable—200% tougher than standard resins—reducing deformation and shrinkage, ensuring precise, high-quality prints. Compatible with most 405nm LCD printers, it’s perfect for detailed miniatures, complex scenes, and professional or hobbyist projects. Plus, its lower odor makes printing more comfortable.

Best For: hobbyists and professionals seeking ultra-fine detail, durability, and a matte finish in miniature models and complex resin prints.

Pros:

- Achieves 14K HD resolution with 0.15mm accuracy for highly detailed prints

- 200% tougher than standard resins, reducing deformation and increasing durability

- Produces a refined matte surface with minimized light interference for realistic visual effects

Cons:

- Slightly higher cost compared to standard resin options

- Requires proper ventilation due to resin fumes despite lower odor formulation

- Compatibility limited to mainstream 405nm LCD resin printers

ANYCUBIC Photon Mono M7 PRO 3D Printer

The ANYCUBIC Photon Mono M7 PRO stands out as an excellent choice for hobbyists and professionals who demand high detail and rapid production for miniatures. Its 14K monochrome LCD offers stunning resolution (13312×5120) and can print holes as small as 0.3mm, capturing intricate details effortlessly. With speeds up to 170mm/h using high-speed resin, it dramatically reduces print times—often under 20 minutes for complex models. Features like auto-leveling, resin auto-fill, and intelligent detection make setup and maintenance straightforward. Although initial Wi-Fi connectivity can be tricky, once stabilized, it enables remote control via the cloud app, boosting efficiency and convenience.

Best For: hobbyists and professionals seeking high-resolution, fast, and cost-effective resin 3D printing for intricate miniatures and detailed models.

Pros:

- Exceptional 14K monochrome LCD resolution for highly detailed prints

- Rapid printing speeds up to 170mm/h significantly reduce production time

- User-friendly features like auto-leveling, auto-fill, and remote control enhance convenience

Cons:

- Initial Wi-Fi setup can be unstable and requires troubleshooting

- Support removal and post-processing can be challenging due to fine features and overexposure risks

- Learning curve involved with optimizing exposure settings and maintenance procedures

Factors to Consider When Choosing Resin 3D Printers for Miniatures

When choosing a resin 3D printer for miniatures, I focus on factors like resolution, resin compatibility, and print speed to guarantee quality and efficiency. Ease of use and maintenance also matter, as they can save time and reduce frustration. Finally, considering durability and post-processing needs helps me pick a printer that fits my workflow and long-term projects.

Resolution and Detail

Choosing a resin 3D printer for miniatures hinges considerably on resolution and detail capabilities. Higher-resolution printers, like those with 8K or 12K screens, deliver incredibly fine details, capturing features down to 17-24μm XY resolution. The XY resolution directly affects how sharp and intricate your models look—smaller pixel sizes mean crisper edges and more textured surfaces. A higher pixel count on the LCD or DLP chip allows tiny features like facial expressions, clothing textures, and delicate accessories to stand out with minimal post-processing. Layer thickness also matters; thinner layers, around 0.05mm or less, produce smoother surfaces and more accurate fine details. Combining high-resolution screens with precise light exposure results in miniature models with exceptional fidelity, reducing the need for extensive sanding or finishing.

Resin Compatibility and Types

Selecting the right resin for your miniature projects requires paying attention to compatibility with your printer’s light source wavelength, which is usually around 405nm. Not all resins work with every printer, so confirming this compatibility is vital. Additionally, different resin types—such as standard, ABS-like, or specialty formulations—offer various properties like detail, strength, and flexibility, which are essential for miniature quality. It’s also important to check if the resin fits your printer’s build volume and resin tray system to avoid fitting issues. Consider whether the resin is designed for high-detail miniatures, providing fine resolution and minimal layer lines. Finally, review the curing and post-processing requirements to ensure your finished miniatures remain durable and true to your expectations.

Print Speed and Efficiency

Optimizing print speed and efficiency is essential for producing miniatures swiftly without sacrificing detail. Faster print speeds, around 130mm/h to 170mm/h, drastically cut down production times. High-resolution screens, like 8K or 12K, allow for detailed miniatures while reducing layer height and exposure time, speeding up the process. Resins formulated for rapid curing, such as fast-acting or high-speed variants, further boost efficiency by solidifying layers more quickly. Efficient resin flow and low viscosity improve layer adhesion and help prevent print failures, saving time on troubleshooting. Automated features like auto-leveling, resin level detection, and failure detection streamline the workflow, minimizing downtime. Together, these factors ensure a smooth balance between speed and precision, making your miniature production more effective.

Ease of Use and Maintenance

When evaluating resin 3D printers for miniatures, ease of use and maintenance are key factors that can make a significant difference in your printing experience. Automatic leveling, self-check features, and intuitive interfaces help beginners get started quickly and reduce setup frustration. Easy-to-clean resin tanks, removable FEP films, and simple support removal save time and effort during post-processing. Compatibility with popular slicing software and clear instructions ensure smooth operation and troubleshooting. Features like resin auto-fill, residue detection, and alert systems for resin levels or print failures streamline ongoing maintenance, minimizing waste and downtime. Additionally, low-odor resins and well-designed ventilation make routine cleaning safer and more comfortable, making overall use more straightforward and less stressful.

Durability and Post-Processing

Since the durability of your miniatures depends heavily on post-processing, it’s crucial to understand how each step affects their strength and longevity. Washing with isopropyl alcohol removes residual resin and surface tackiness, while UV curing solidifies the model, increasing hardness and impact resistance. Using a resin with low shrinkage helps minimize warping, preserving the model’s dimensions and structural integrity. Proper support removal and surface finishing reduce stress points that might cause cracking or breakage over time. The toughness of the resin directly impacts how well your miniatures withstand handling, chipping, and gameplay wear. Post-curing enhances the cross-linking of resin molecules, considerably boosting durability. Paying attention to these steps ensures your miniatures remain detailed, strong, and durable long after printing.

Frequently Asked Questions

How Do Resin Types Affect Miniature Detail Quality?

Different resin types markedly impact miniature detail quality. I’ve found that high-resolution, clear or grey resins capture fine details better, making your miniatures look sharper and more realistic. Some specialty resins, like tough or flexible ones, can slightly soften details but add durability. Overall, choosing the right resin depends on whether you prioritize extreme detail or specific mechanical properties, but clear or standard resin usually offers the best fine detail for miniatures.

What Safety Precautions Are Necessary When Handling Resin?

When handling resin, I always wear gloves and eye protection to avoid skin contact and splashes. I work in a well-ventilated area to prevent inhaling fumes. I keep my workspace clean and dispose of leftover resin and cured parts properly. Additionally, I avoid eating or drinking nearby, and I always wash my hands thoroughly afterward. Safety is key to enjoying resin printing without health risks.

How Does Exposure Time Influence Miniature Resolution?

Exposure time directly impacts miniature resolution by controlling how long resin is cured. Too short, and details remain incomplete, resulting in rough surfaces. Too long, and the resin over-curves, blurring fine details and reducing accuracy. Finding the right balance is key—short enough for sharp detail, long enough for complete curing. I always experiment with exposure settings to optimize clarity, precision, and overall quality for my miniatures.

Can Resin Printers Print Multi-Color Miniatures?

Yes, resin printers can print multi-color miniatures, but it’s not straightforward. I’ve found that using multi-material or color-changing resins can work, though the color options are limited. Some printers support resin cartridges with different shades, allowing for multi-color printing. Alternatively, post-processing with paints is common to achieve vibrant, detailed miniatures. It’s a fun challenge that adds a lot of personality to your models!

What Is the Typical Lifespan of Resin Printer Components?

Think of resin printer components like delicate gears in a watch—they last a good while but need care. Typically, the LCD screen and laser tube last around 1,000 to 2,000 hours of use, while the build plate and vat might endure 300 to 500 prints. Regular maintenance, proper cleaning, and using quality resin can extend their lifespan, ensuring your miniatures turn out perfect every time.

Conclusion

Choosing the right resin 3D printer can truly elevate your miniature game, but the perfect match isn’t always obvious. With so many top-tier options like ELEGOO’s ultra-high resolution models and ANYCUBIC’s detail-rich printers, I’m excited to see which one will push your creativity to new heights. The best choice might just be around the corner—ready to unleash astonishing detail and precision you never thought possible. Are you prepared to take that next leap?