Structural battery composites combine energy storage with load-bearing functions, helping you build lighter, more efficient vehicles. By integrating electrochemical components into strong materials like carbon fibers and polymers, you can reduce weight while maintaining strength. Although manufacturing these composites is complex and challenging, advances are making production more reliable. If you want to discover how these innovations can revolutionize vehicle design and energy use, keep exploring the latest developments in this exciting field.

Key Takeaways

- Structural battery composites combine load-bearing and energy storage, reducing vehicle weight and improving efficiency.

- Material integration involves blending carbon fibers, polymers, and electrochemical components for both strength and energy capacity.

- Manufacturing challenges include embedding electrochemical elements without compromising structural integrity.

- Scaling production requires advanced fabrication techniques to ensure quality, consistency, and durability.

- Ongoing research aims to develop reliable, lightweight composites that enable lighter vehicles and enhanced energy systems.

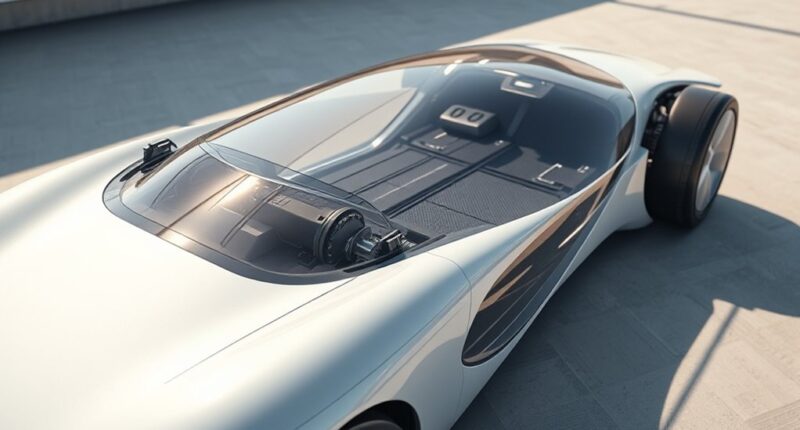

Structural battery composites are innovative materials that combine the functions of load-bearing structures and energy storage into a single component. This integration offers a promising way to reduce weight and improve efficiency in various applications, especially in transportation. When you work with these composites, you’re dealing with a sophisticated blend of materials designed to serve dual purposes, which means material integration is a critical factor. You need to carefully select and combine components like carbon fibers, polymers, and electrochemical elements to guarantee both structural integrity and ideal energy storage capacity. Achieving this balance requires a deep understanding of the interactions between materials so that the composite can withstand mechanical stresses while effectively storing and releasing energy.

One of the major hurdles you face with structural battery composites is manufacturing challenges. These challenges stem from the complexity of integrating energy storage components within structural materials without compromising either function. Traditional manufacturing processes often fall short because they are not designed for this level of material integration. For example, embedding electrochemical elements into composite layers can introduce defects, weaken the material, or cause inconsistent performance. You have to develop specialized fabrication techniques, such as advanced layering, precise resin infusion, or novel curing methods, to guarantee uniform distribution of electrochemical components and maintain the composite’s strength. Material integration is a key factor influencing the success of these composites.

Additionally, manufacturing at scale presents its own set of difficulties. You need to ensure quality control and repeatability across multiple units, which can be tricky when working with multi-functional materials. Handling delicate electrochemical parts during manufacturing without damaging them or affecting their performance requires precision equipment and processes. The challenge is also to produce composites that are lightweight yet durable enough for real-world use. You might have to experiment with different material combinations and process parameters to optimize performance and manufacturability simultaneously.

Despite these manufacturing challenges, progress is being made. Researchers and engineers are developing new techniques and materials to streamline production and enhance reliability. For you, understanding these advances is key to implementing structural battery composites effectively. As these materials mature, the potential to create lighter vehicles and more efficient energy systems becomes increasingly tangible. By addressing material integration and manufacturing challenges head-on, you’ll be at the forefront of transforming how energy storage and structural functions coexist within a single component, paving the way for innovative, lighter, and more efficient designs.

Frequently Asked Questions

What Are the Environmental Impacts of Manufacturing Structural Battery Composites?

You’ll want to contemplate the environmental footprint of manufacturing structural battery composites, as it can be significant due to resource extraction and energy use. These processes may impact resource sustainability by depleting raw materials like lithium and carbon fibers. However, advancements aim to reduce these impacts, making production more eco-friendly. By choosing sustainable materials and cleaner manufacturing methods, you can help minimize the environmental footprint and support resource conservation efforts.

How Do Structural Battery Composites Compare Cost-Wise to Traditional Materials?

Imagine you’re stepping into the future, but today, structural battery composites tend to be more expensive than traditional materials. Their cost comparison shows higher material affordability challenges due to complex manufacturing and advanced components. However, as technology advances, prices are expected to decrease, making them more competitive. Right now, they may cost more initially, but their lightweight and energy storage benefits could save you money in the long run.

Can These Composites Be Recycled or Reused Effectively?

You can recycle structural battery composites, but recycling challenges remain due to their complex materials. Effective reuse potential exists if you carefully design them for disassembly and recycling processes. Advances are making it easier to recover valuable components, yet you need to think about the difficulty of separating different materials. Overall, with ongoing innovations, these composites could become more recyclable and reusable, helping reduce waste and promote sustainability in the future.

What Are the Safety Concerns Associated With Structural Battery Composites?

Think of structural battery composites as a double-edged sword—powerful but potentially dangerous. You should be aware of fire hazards, especially if the materials are damaged or improperly handled, threatening the structural integrity of the vehicle. These risks require rigorous safety measures, such as fire-resistant barriers and careful manufacturing, to guarantee you’re protected. Safety concerns can’t be overlooked, as they directly impact both performance and your well-being.

How Do They Perform Under Extreme Temperature Conditions?

You’ll find that structural battery composites perform well under extreme temperatures due to their high thermal stability, maintaining their integrity without degrading. Their mechanical resilience ensures they withstand temperature fluctuations, preventing cracks or failures. However, prolonged exposure to very high or low temperatures can challenge their performance, so proper thermal management remains essential. Overall, their design aims to balance thermal stability and mechanical resilience for reliable operation in diverse conditions.

Conclusion

By integrating structural battery composites into vehicle design, you’re fundamentally weaving the future’s fabric—where strength and energy intertwine seamlessly. This innovation transforms your vehicle into a living, breathing entity that’s lighter, more efficient, and ready to carry the weight of tomorrow’s dreams. As you embrace these materials, you’re not just building better cars; you’re shaping a new horizon where energy flows as naturally as blood through veins, fueling progress with every mile.