Digital twins are virtual replicas of physical assets or systems that let you simulate, analyze, and improve real-world operations safely and efficiently. By integrating sensor data and advanced modeling, you can predict issues before they happen and optimize performance proactively. They help you test changes virtually, reducing risk and downtime. As you explore further, you’ll uncover how these digital models can transform your decision-making and drive innovation across industries.

Key Takeaways

- Digital twins create accurate virtual replicas for simulating real-world scenarios and testing innovations risk-free.

- They integrate sensor and IoT data for real-time monitoring and continuous updates of physical assets.

- Predictive analytics enable proactive maintenance, reducing downtime and preventing equipment failures.

- Virtual testing allows evaluation of new configurations and processes before physical deployment.

- Advanced simulation and AI security enhance decision-making, foster innovation, and ensure system reliability.

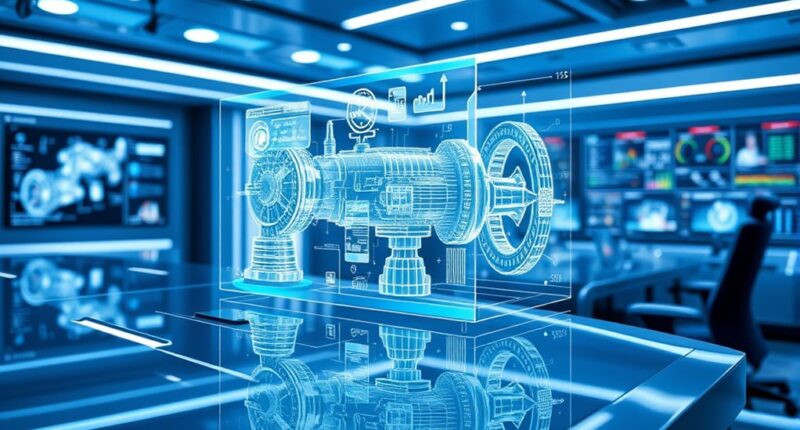

Have you ever wondered how industries are transforming their operations with advanced technology? One of the most exciting innovations is the development of digital twins. These virtual replicas of physical assets, processes, or systems allow you to simulate real-world scenarios with remarkable accuracy. By creating a virtual model, you can analyze the behavior of equipment or workflows without risking downtime or costly mistakes. This approach gives you a detailed, real-time view of your operations, empowering you to make smarter decisions faster.

Virtual modeling is at the core of digital twins. It involves building a precise digital replica that reflects the current state of its physical counterpart, incorporating data from sensors and IoT devices. This detailed virtual model enables continuous monitoring and testing, so you can experiment with modifications and predict outcomes without disrupting actual operations. As a result, you gain deeper insights into how your assets perform under different conditions, helping you optimize maintenance schedules, improve efficiency, and extend equipment lifespan.

Predictive analytics further enhances the power of digital twins. By analyzing historical and real-time data through advanced algorithms, predictive analytics forecasts potential issues before they escalate into failures. Imagine being able to anticipate equipment breakdowns or process bottlenecks beforehand, so you can schedule maintenance or adjustments proactively. This proactive approach minimizes downtime, reduces costs, and increases overall productivity. It’s like having a crystal ball that shows you future challenges, allowing you to prepare and respond effectively.

Together, virtual modeling and predictive analytics make digital twins an invaluable tool for innovation. They enable you to simulate different scenarios, evaluate the impact of changes, and optimize operations in a risk-free environment. For instance, in manufacturing, you can test new process configurations virtually, saving time and resources before implementing them on the factory floor. In energy sectors, digital twins help monitor turbines or grids, predicting failures and ensuring continuous operation. This blend of virtual modeling and data-driven forecasting not only boosts efficiency but also fosters a culture of continuous improvement.

Ultimately, digital twins help you stay ahead of the competition by providing actionable insights and reducing uncertainties. They turn complex data into strategic advantages, allowing you to innovate faster and more confidently. As these technologies evolve, your ability to simulate reality and predict future outcomes will become even more precise, opening new possibilities for industries across the board. Embracing digital twins means you’re not just reacting to problems — you’re proactively shaping the future of your operations. Additionally, integrating AI security into digital twin systems is essential to safeguard sensitive data and ensure reliable performance as these technologies become more interconnected.

Frequently Asked Questions

How Do Digital Twins Adapt to Real-Time Environmental Changes?

You guarantee your digital twins adapt to real-time environmental changes by continuously updating with sensor calibration and data synchronization. Sensors collect live data, and you calibrate them regularly to maintain accuracy. Then, you synchronize this data with the digital twin, allowing it to reflect current conditions. This real-time updating helps you make informed decisions and optimize operations effectively, keeping your digital twin aligned with the actual environment.

What Industries Benefit Most From Digital Twin Technology?

You’ll find industries like healthcare applications and urban planning benefit most from digital twin technology. In healthcare, digital twins help simulate patient conditions for personalized treatment. Urban planners use them to model city infrastructure, improving development and sustainability. These applications allow you to test scenarios virtually, reducing risks and costs. As a result, digital twins drive innovation, enhance decision-making, and optimize outcomes in these dynamic sectors.

How Secure Is Data Within Digital Twin Systems?

While digital twin systems are designed with robust security measures, no system is completely impervious. You get the best protection through data encryption and strict access control, which help safeguard sensitive information. Regular security updates and vigilant monitoring ensure your data remains private. Though some risks exist, implementing these best practices substantially reduces the likelihood of breaches, giving you peace of mind as you innovate with digital twin technology.

What Are the Initial Costs of Implementing Digital Twins?

The initial costs of implementing digital twins vary based on your project scope, technology needs, and integration complexities. You should consider cost considerations like hardware, software, data infrastructure, and skilled personnel. Implementation challenges may include aligning systems, ensuring data accuracy, and training staff. While upfront expenses can be significant, investing wisely can lead to long-term benefits through improved efficiency, predictive maintenance, and innovation in your operations.

How Do Digital Twins Improve Predictive Maintenance Accuracy?

You’ll see a 20-30% boost in predictive maintenance accuracy when you use digital twins. They improve this by leveraging precise sensor calibration and seamless data integration, providing real-time insights. This means you can identify issues earlier and reduce downtime. By continuously updating the twin with current data, you enhance fault detection and maintenance planning, making your operations smarter and more reliable.

Conclusion

Digital twins are like mirrors reflecting the future of innovation. By simulating reality, you can anticipate problems, optimize processes, and unlock new opportunities. Embracing this technology is like planting seeds today for a smarter, more efficient tomorrow. As you harness digital twins, you’ll find yourself steering through complex systems with the ease of a skilled sailor guiding through calm waters. Ultimately, they’re your map to transforming ideas into reality, making innovation feel almost effortless.